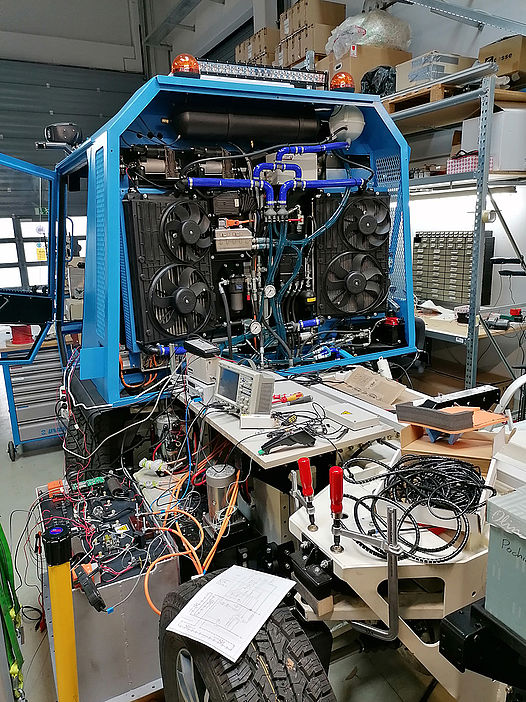

Rethinking the vehicle. As part of a research project, a completely new type of multi-purpose electric vehicle was designed for use in municipalities and in agriculture and forestry. Thanks to its modular design, it can be adapted very easily to the respective requirements.

„You have to rethink the entire vehicle“